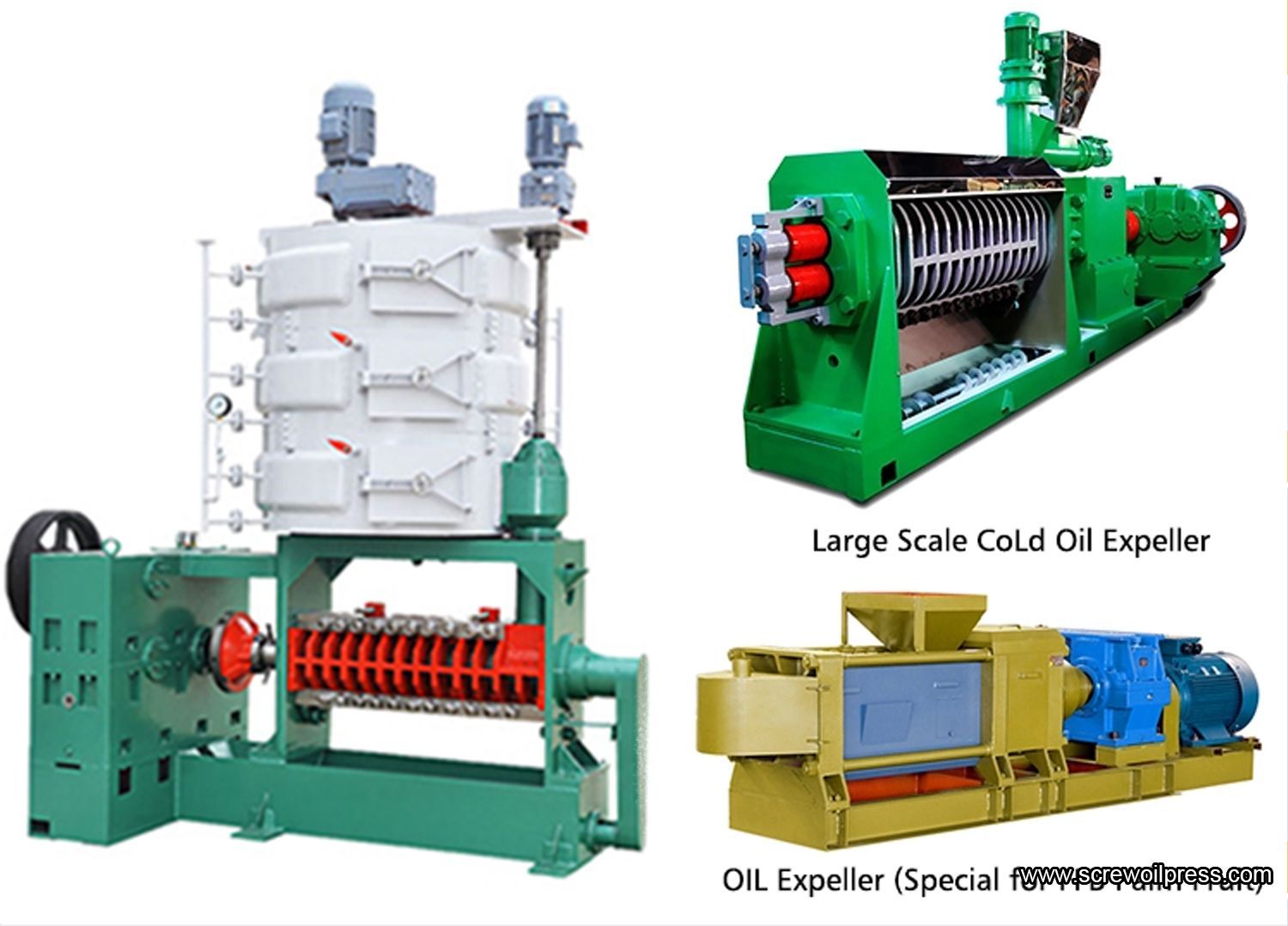

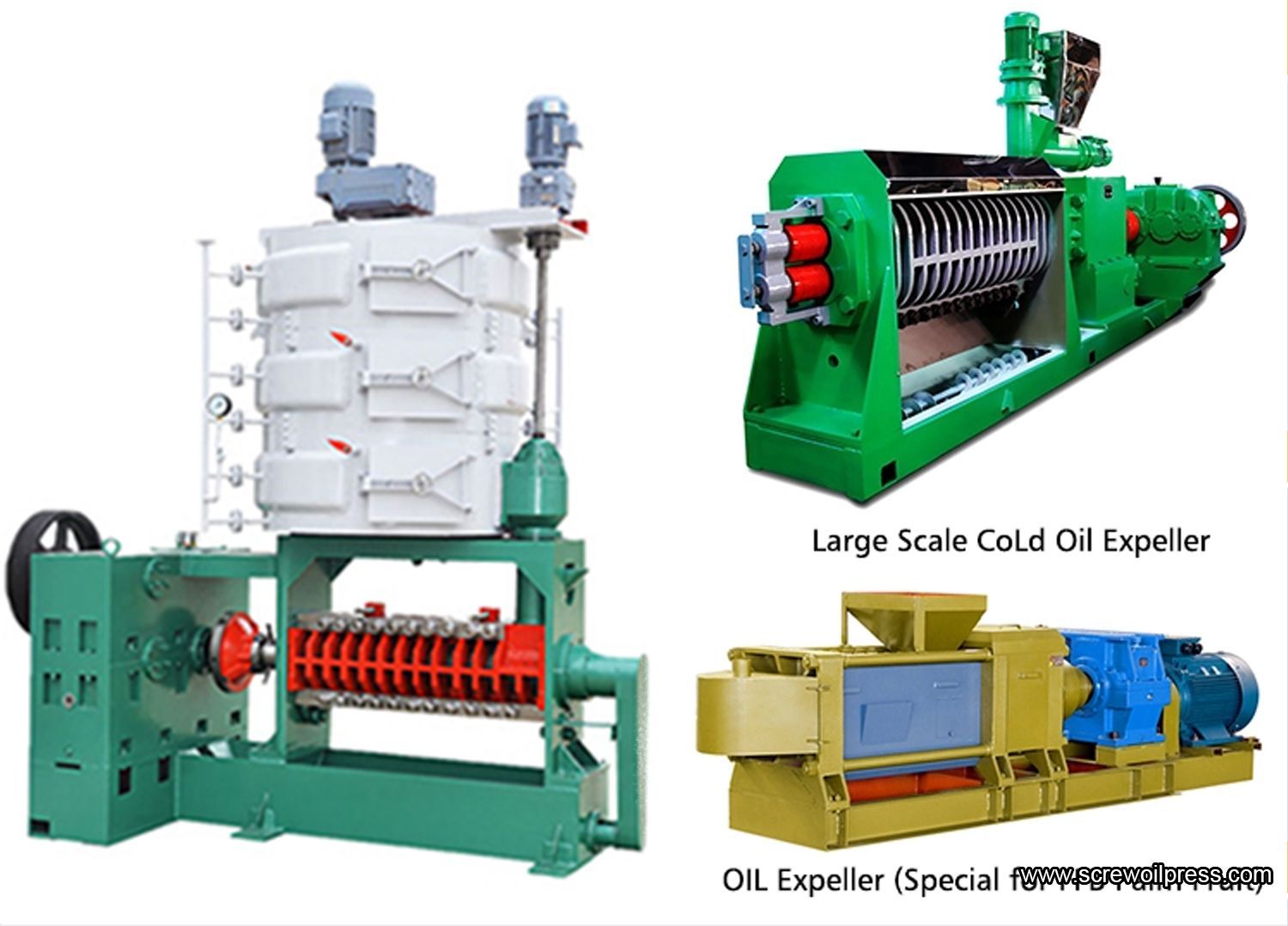

- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

NEWS

Oil Press Suction Pump No Suction How To Solve

Time:Fri-05-23 hits:

Buy oil press to learn to repair and maintenance, with a long time, there will be some minor problems. If not solved in time, the construction period will be delayed, resulting in losses, so we should learn to solve by ourselves.

How to solve the suction pump suction, in strict accordance with the instructions. Before starting, it is necessary to preheat and clean up the sediment inside the machine in time.

The following is the common problems and treatment of oil press oil pump:

1. The oil pump does not absorb oil.

Dirt clogging the oil filter is easy to cause the oil pump of the hydraulic oil press to not suck oil, so the oil filter should be removed and washed.

· If the oil is used for a long time and the sediment is attached to the oil inlet valve and the valve is not tight, the new oil should be replaced or the old oil should be released to filter and clean the oil inlet valve.

· If it is caused by insufficient oil in the tank, just add enough oil to the tank.

· If there is no vacuum in the oil pump, the small piston can be pulled out and injected into the oil before pressure.

2. Insufficient pressure of oil pump

· If the valve has dirt or poor seal, it can be ground after disassembly and pouring to make it close.

· If the oil inlet valve plug of the oil press has poor contact with the valve seat, it can also be cleaned and ground to make it close.

· In case of oil leakage caused by poor contact between the plug in and out of the oil press and the valve seat or not tightened, the oil inlet plug and the valve seat of the oil press can be ground to make it close or tighten the plug.

· If the clearance between the small piston and the pump body is too large after grinding, the pump should be replaced.

3. The cylinder and piston of the oil press leak oil

· If the mouth of the leather bowl is incorrectly installed upward, the leather bowl should be reloaded in the correct way; If the leather bowl is broken and damaged, we will replace it.

4, safety valve failure

· If the ball valve is not sealed due to dirt in the oil, the safety valve should be cleaned to remove dirt and make the ball valve close.

· If the spring loses elasticity and cannot withstand high pressure, it should be replaced with a new spring; If the adjusting screw is loose, resulting in not to the specified pressure on the valve, should adjust the screw again, so that the pressure reaches the specified pressure before the valve.

· If overpressure operation is frequent. It is easy to cause the steel ball valve to be bruised. It is necessary to re-grind the valve, replace the steel ball and pay attention to the operation according to the operating rules.