- Oil Mill Machinery

- Oil Refinery Machinery

- Oil Processing Plant

- Solvent Extraction Plant

- Animal Oil Processing Machine

- Feed Processing Machine

- Palm Oil Mill

- Industrial Drying Machine

- Grain Processing Machinery

NEWS

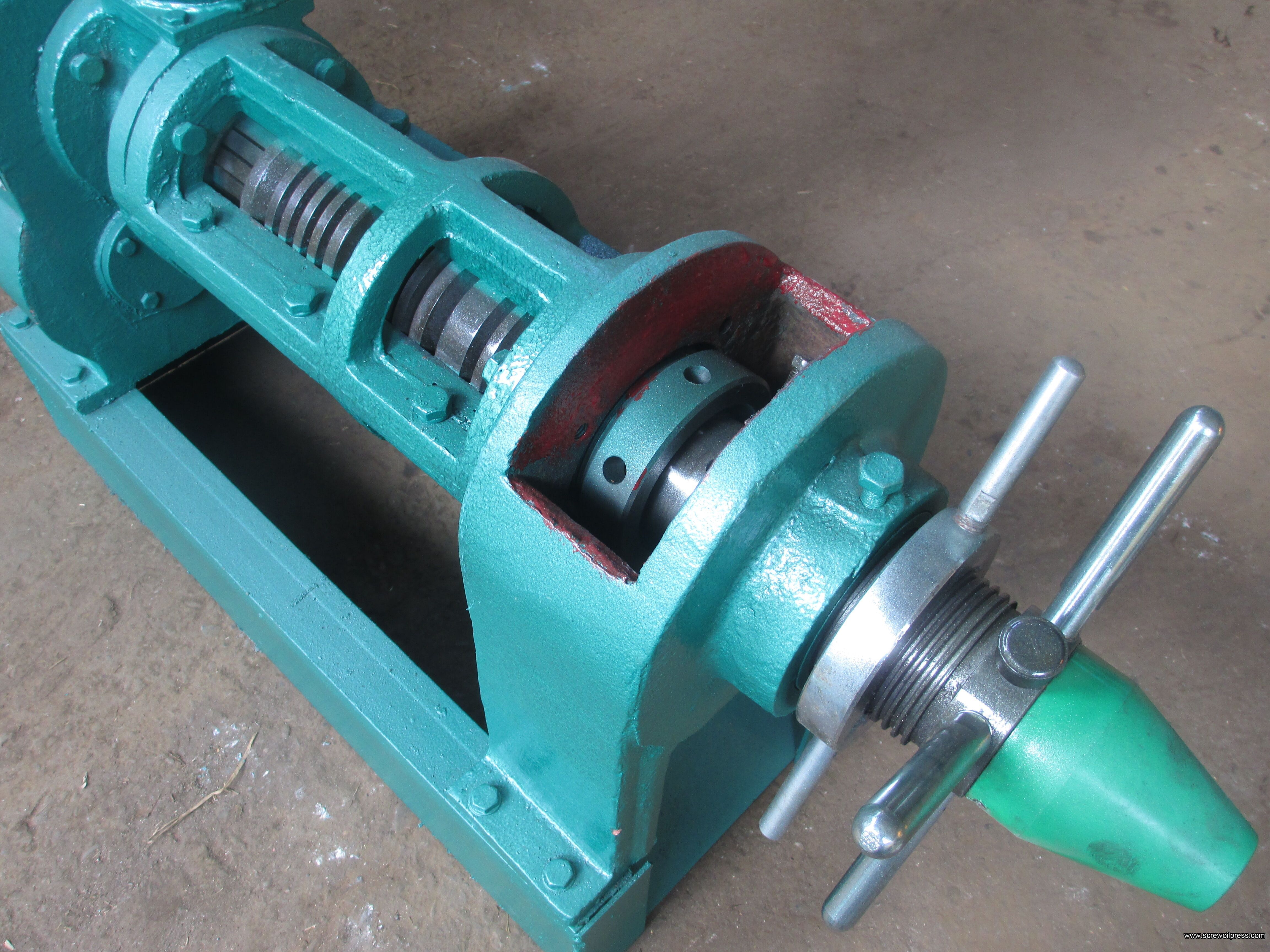

How to Address Excessive Residue in Oil Produced by Screw Oil Presses?

After using a screw oil press for some time, many users notice that the oil extracted contains more impurities than when the machine was new.

What exactly causes this? Is it due to poor machine quality? Incorrect operation?

Excessive residue in oil from screw presses is typically related to equipment adjustments, raw material processing, or component conditions. Troubleshoot and address the issue using the following steps:

I. Inspect and Adjust Core Parameters of the Press Chamber

1. Calibrate the gap between the screw and the cage

- If the gap is too large (exceeding 0.3-0.5mm), residue may flow out with the oil.

Shut down the machine and measure with a feeler gauge. Use the cake-forming mechanism to fine-tune the cake thickness (typically set to 1-2mm) to reduce the chamber gap.

- Note: Optimal gaps vary by oilseed type (e.g., slightly larger for peanuts, smaller for rapeseed). Excessive reduction may cause material blockage.

2. Control pressing pressure and feed rate

- Insufficient pressure prevents adequate compression of the cake, resulting in high oil content in the residue and oil contaminated with residue.

Increase chamber pressure by adjusting gearbox speed (reducing feed rate) or increasing the pitch gradient of the screw.

- Sudden pressure spikes causing cake charring will also introduce broken cake into the oil. Maintain chamber temperature between 80-120°C (adjust based on oilseed type) via the temperature control system.

II. Optimizing Raw Material Pretreatment

1. Controlling Moisture Content and Crushing Degree

- Excessive moisture (e.g., peanuts exceeding 10%) causes cake adhesion, forming paste-like residue;

- Insufficient moisture leads to brittle cakes and fine residue.

Adjust moisture to 6%-8% (varies by oilseed type) via drying or water spraying.

- Uneven crushing size impedes thorough pressing. Ensure consistent particle size after crushing (e.g., soybeans crushed into 2-4 pieces).

2. Remove impurities from raw materials

- Impurities like soil and stones in raw materials can scratch the press chamber and contaminate the oil with debris.

Impurities must be removed before feeding using screen filtration and magnetic separation equipment.

III. Inspecting Key Equipment Components

1. Checking Screw and Cage Wear

- Wear on screw threads (e.g., grooves) or increased gaps between cage rings compromises sealing, causing residue leakage. Replace worn parts and ensure surfaces are smooth and burr-free.

- Regularly clean residual pulp from cage gaps to prevent blockages forcing oil-pulp mixture discharge.

2. Filter System Maintenance

- If equipped with built-in oil filtration (e.g., mesh screens, filter cloths), inspect for clogging or damage. Clean or replace promptly (recommended 80-120 mesh screens; adjust based on oil quality).

- After oil extraction, implement secondary filtration (e.g., centrifugal oil separator, plate-and-frame filter) to further remove residues.

IV. Standard Operating Procedures

1. Avoid Overloading Feed

- Excessive feed rate causes uneven distribution of material in the chamber, leading to localized under-pressing and excessive fine residue.

Control feed rate via the hopper regulator to maintain uniform material supply.

2. Perform Regular Shutdown Cleaning

- Residual burnt material in the chamber after continuous operation forms hardened residue that contaminates fresh oil.

After shutdown, clean residual material from the chamber, screw, and cake outlet.

Following these steps effectively reduces residue content in the extracted oil.

If adjustments yield no improvement, consider oil characteristics (e.g., high-fiber raw materials may require specialized screw designs) or equipment model compatibility issues. Contact the manufacturer for customized components or upgrades when necessary.

We provide a complete set of engineering equipment for plant and animal oil processing, and a complete set of processing equipment such as cooking machines, presses, dryers, crushers, centrifuges, thickeners, evaporators, etc., adopting mature European technology, and provide solutions for construction, installation, commissioning and operation Training.